Reducing Labor and Costs: The Economic Impact of Smart Farming

The global agricultural sector is at a critical juncture. Faced with rising operational costs, an aging workforce, and increasing regulatory pressure, traditional livestock farming models are becoming economically unsustainable. For the swine industry, in particular, the challenges of labor-intensive monitoring, disease management, and feed optimization represent significant drains on profitability. The solution is not merely incremental improvement, but a fundamental shift: the adoption of smart farming technology.

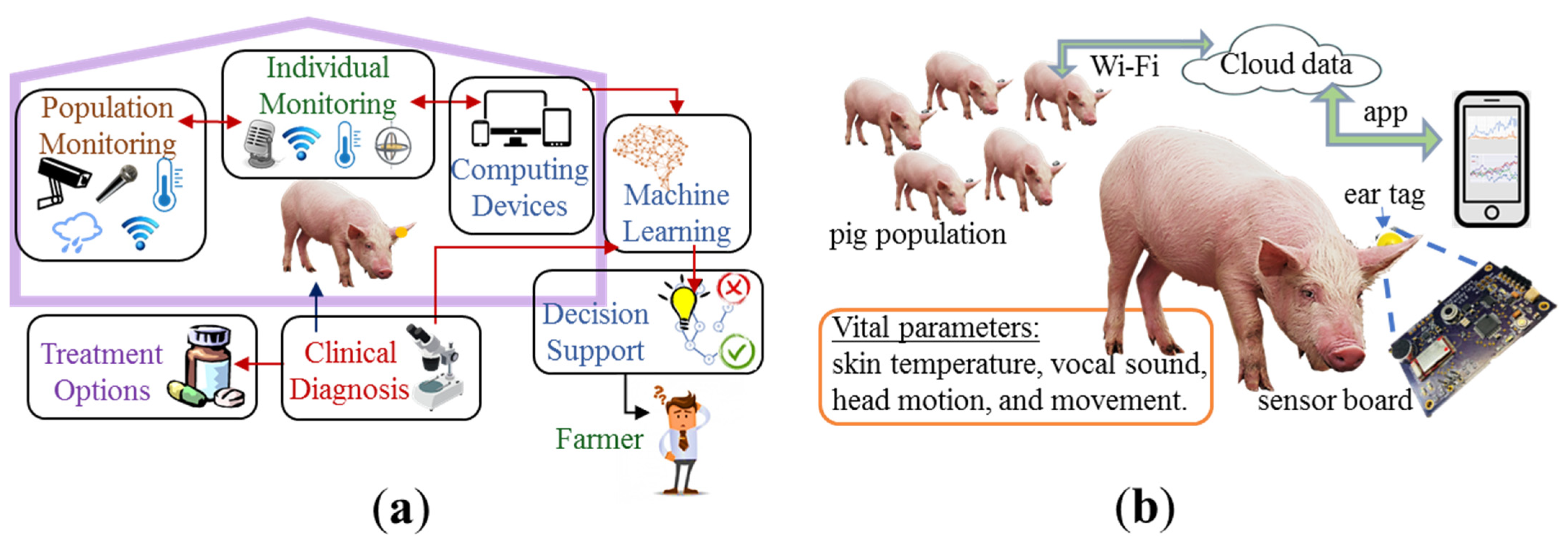

This is where Trackfarm emerges as a transformative force. By leveraging deep tech—specifically AI, computer vision, and advanced sensor networks—Trackfarm is redefining the economics of pig farming. It is a comprehensive solution designed not just to monitor, but to actively manage and optimize every aspect of the farm, delivering a clear, measurable return on investment by drastically reducing the two most critical variables: labor and operational costs.

The Labor Crisis and the Automation Imperative

Manual labor in a large-scale pig operation is demanding, repetitive, and prone to human error. Tasks such as individual animal observation, manual weighing, and environmental control checks consume countless hours that could be better spent on strategic farm management. The scarcity of skilled farm labor only exacerbates this issue, driving up wages and increasing turnover.

Trackfarm’s AI-powered automation directly addresses this labor crisis.

Continuous, Unblinking Monitoring: Instead of a farmer walking the barns multiple times a day to visually check on thousands of animals, Trackfarm’s computer vision systems provide 24/7 surveillance. The AI monitors pig behavior, movement patterns, and feeding habits. This continuous, automated observation replaces hours of manual inspection, allowing farm staff to focus their limited time on intervention and maintenance, rather than mere detection.

Automated Environmental Control: Maintaining optimal temperature, humidity, and ventilation is crucial for pig health and growth, yet manual adjustments are often reactive and inconsistent. Trackfarm integrates with climate control systems, using real-time data from sensors to make precise, proactive adjustments. This not only saves labor but also ensures the pigs are always in their ideal growth environment, leading to better feed conversion ratios and faster time to market.

The net effect is a significant reduction in the required labor hours per pig, translating directly into lower payroll expenses and a more efficient allocation of human capital.

Precision Health: From Reactive Treatment to Proactive Prevention

Disease outbreaks are the single largest threat to a pig farm’s economic viability. A single case of illness can spread rapidly, leading to high mortality rates, expensive veterinary treatments, and significant losses in productivity. Traditional methods rely on visual symptoms, which often appear too late for effective containment.

Trackfarm’s AI excels at early disease detection, turning the health management model from reactive treatment to proactive prevention.

Behavioral Anomaly Detection: The system analyzes subtle changes in a pig’s behavior—such as reduced activity, changes in posture, or isolation from the group—long before a human observer would notice physical symptoms. Early alerts allow for immediate isolation and treatment of the affected animal, preventing the spread of disease to the rest of the herd.

Automated Weight and Growth Tracking: Manual weighing is stressful for the animals and labor-intensive for the staff. Trackfarm uses non-contact computer vision to estimate the weight of every pig daily. This precise data allows farmers to identify underperforming animals early, adjust their feed regimen, and ensure the entire batch reaches market weight simultaneously, maximizing efficiency and minimizing the time the animals spend on the farm.

The economic benefit of this precision is stark. Reduced mortality, lower veterinary bills, and optimized growth cycles all contribute to a healthier bottom line.

| Metric | Traditional Farming | Trackfarm Smart Farming | Economic Impact |

|---|---|---|---|

| Mortality Rate | 3.5% – 5.0% | < 2.0% | Significant reduction in loss of stock |

| Disease Detection | Reactive (Visual Symptoms) | Proactive (Behavioral AI) | Faster intervention, lower treatment cost |

| Labor Hours/Day | High (8-10 hours/barn) | Low (2-3 hours/barn) | Up to 70% labor cost reduction |

| Feed Conversion Ratio (FCR) | Variable, often sub-optimal | Optimized by precise data | Reduced feed waste, faster growth |

| Time to Market | Less predictable | Highly predictable | Improved cash flow and planning |

Optimizing Feed and Resource Utilization

Feed accounts for the largest portion of a pig farm’s operating budget—often 60% to 70% of total costs. Even minor inefficiencies in feed management can result in massive financial losses over a year. Trackfarm provides the tools to manage this cost center with unprecedented precision.

Individualized Feeding Strategies: By continuously tracking the weight and growth curve of each pig, the system can inform automated feeding systems to deliver the exact nutritional requirements. This eliminates overfeeding (waste) and underfeeding (stunted growth), ensuring every kilogram of feed is converted into market weight as efficiently as possible.

Waste Reduction and Sustainability: Smart systems also monitor water consumption and waste output. By identifying and addressing leaks or abnormal consumption patterns immediately, Trackfarm helps conserve resources and reduce the environmental footprint, which is increasingly important for regulatory compliance and market access. The data collected can also be used to optimize manure management, turning a cost into a potential revenue stream (e.g., biogas production).

Data-Driven Productivity: Maximizing Yield and ROI

The true power of Trackfarm lies in its ability to transform raw farm data into actionable business intelligence. Traditional farming relies on intuition and periodic sampling; smart farming relies on continuous, comprehensive data streams.

Predictive Analytics for Breeding: For breeding operations, the system can track sow health, estrus cycles, and litter performance with high accuracy. Predictive models help farmers optimize insemination timing and identify the most productive bloodlines, leading to larger, healthier litters and a more predictable supply chain.

Performance Benchmarking: Trackfarm aggregates data across multiple barns or even multiple farms, providing farmers with detailed performance benchmarks. This allows them to identify best practices, pinpoint underperforming areas, and make evidence-based decisions to continuously improve efficiency. This data-driven approach is the key to scaling operations without sacrificing quality or increasing costs disproportionately.

The Economic Case for Trackfarm: A Hypothetical Scenario

Consider a medium-sized farm with 5,000 finishing pigs per cycle.

| Cost/Benefit Factor | Traditional Annual Cost | Trackfarm Annual Cost (Estimated) | Annual Savings |

|---|---|---|---|

| Labor | \$150,000 | \$50,000 (Reduced by 66%) | \$100,000 |

| Feed Waste | \$50,000 (Estimated 2% waste) | \$10,000 (Reduced by 80%) | \$40,000 |

| Mortality Loss | \$45,000 (3% loss) | \$15,000 (1% loss) | \$30,000 |

| Veterinary/Treatment | \$20,000 | \$10,000 (Early detection) | \$10,000 |

| Total Savings | – | – | \$180,000 |

Note: These figures are illustrative and based on industry averages and the projected efficiency gains from Trackfarm’s technology.

This substantial annual saving demonstrates that the initial investment in a smart farming system is not merely an expense, but a strategic capital expenditure with a rapid and compelling return on investment (ROI). The reduction in labor and costs creates a significant competitive advantage in a volatile market.

Beyond the Farm Gate: Biosecurity and Market Resilience

The economic impact of Trackfarm extends beyond internal cost savings. In the modern global market, biosecurity and sustainability are increasingly becoming prerequisites for market access and premium pricing.

Enhanced Biosecurity: Trackfarm’s automated monitoring reduces the need for human entry into high-risk zones, minimizing the vector for disease transmission. The system can also integrate thermal imaging and other sensors to detect external threats or unauthorized access, providing an unparalleled layer of biosecurity that protects the entire operation.

Meeting Consumer Demand: Consumers and regulators are demanding higher standards of animal welfare and environmental stewardship. Trackfarm provides verifiable, continuous data on animal health, behavior, and environmental conditions. This transparency allows farmers to demonstrate compliance and market their products as ethically and sustainably produced, potentially unlocking access to higher-value markets.

The Future of Farming is Smart, Sustainable, and Profitable

Trackfarm is more than just a collection of sensors and cameras; it is an integrated intelligence platform that empowers farmers to move from managing crises to managing profitability. By automating the mundane, optimizing the expensive, and predicting the unpredictable, Trackfarm ensures that the future of pig farming is one of reduced labor, lower costs, and maximized economic output.

The transition to smart farming is no longer optional—it is essential for survival and success in the 21st-century agricultural economy. Trackfarm provides the proven technology and the clear economic pathway to make that transition a reality.